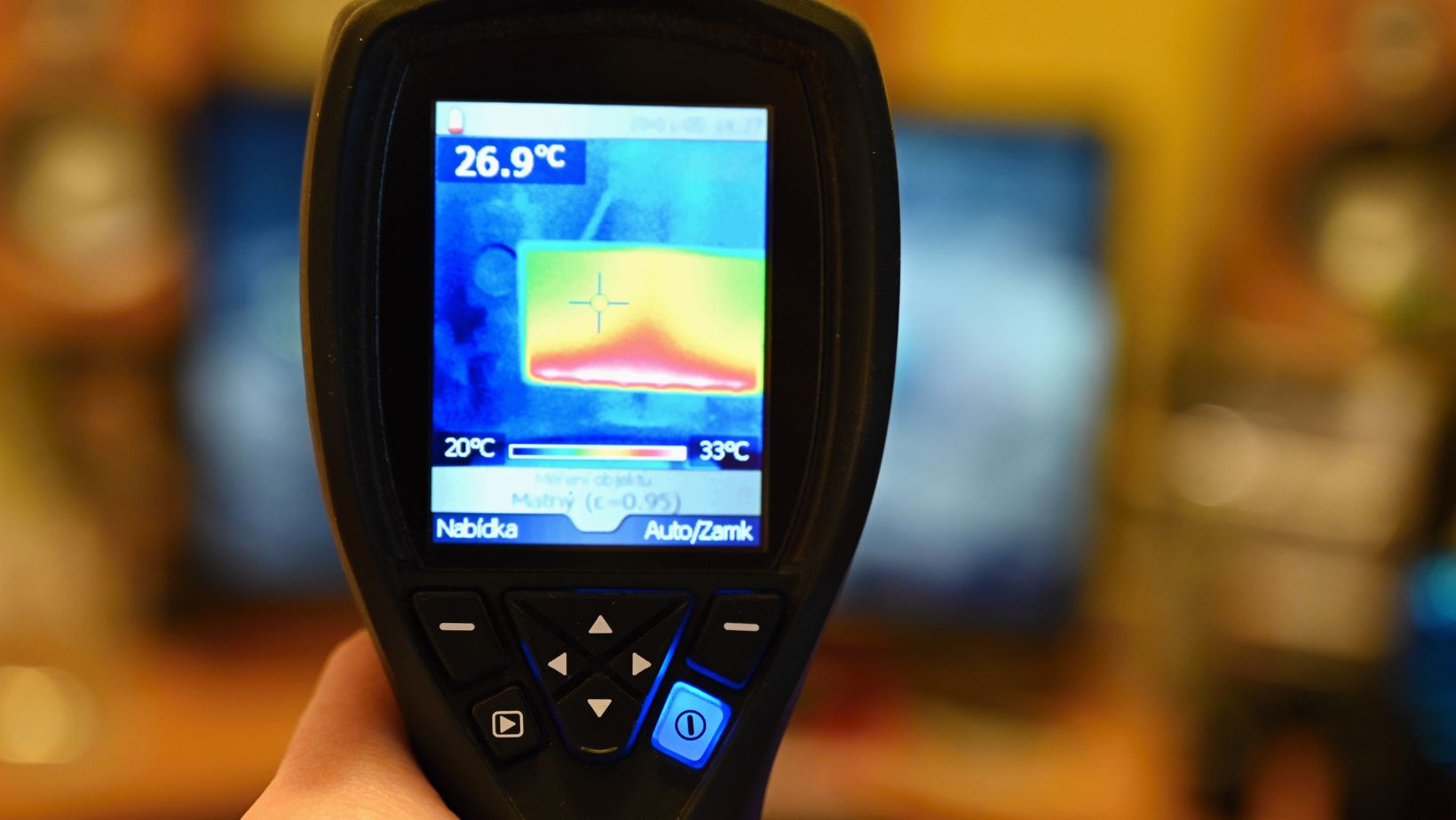

Thermal imaging cameras have gone in a generation from rarefied industrial usage to general commercial products and even for construction, home inspections, firefighting, or wildlife observation. These heat signature cameras pick up heat signatures and convert them into visual images, making the invisible visible. Thermal imaging cameras, however, are not all made equal. From a professional to a hobbyist, knowing which features to look for makes a big difference in the performance and value you get.

Let’s explore the components to look for before buying your next device.

Resolution: See the Details For What They Are

The thermal resolution is what determines the clarity & detail of the resulting thermal image that the device produces. The higher the resolution (160×120/320×240, etc.), the more detail the camera can capture. It may be vital when examining intricate systems such as electrical panels or HVAC devices where minor temperature variances may reveal significant issues. For professional-level inspections, seek out a camera with a minimum of 320×240 resolution. Lower resolution may be acceptable for casual users, but the more detail, the more effective your readings and analyses can be.

Temperature Limits and Sensitivity: Understand Your Boundaries

Not all thermal imaging cameras are suitable for every job. One key consideration is the temperature range the camera can read — the minimum and maximum temperatures it can accurately capture.

Cameras for industrial or firefighting applications require a broader temperature range (potentially -20°C to 1000°C). Temperature sensitivity ( thermal sensitivity or NETD (Noise Equivalent Temperature Difference)) is another key factor. The lower the NETD (say, <0.05°C), the more sensitive the camera is to the minutest temperature change, providing greater imaging accuracy that could be useful when inspecting buildings or medical screenings.

Field of View (FOV): What You See in the Frame

The Field of View is the amount of visible space at any given time. A wider FOV is helpful for quickly scanning large areas such as open fields or roofs while a narrower FOV is better for looking at specific objects far away. Ensure that the FOV is compatible with your primary application, as that often prevents you from having to purchase expensive additional lenses later.

Durability and Ergonomics: Designed for the Real World

Thermal cameras are often used in extreme conditions—outside, at heights, and within mounting stress environments. Devices must be rugged, with ratings like IP54 or IP65 for dust and water resistance. Due to ergonomic design considerations, handheld usage over longer duration is also essential. Usability and fatigue during long inspections can be significantly affected by lightweight construction, guided button layouts, and grips.

Software and Connectivity: More Intelligent Inspections

Today’s thermal imaging cameras often have software for advanced image analysis, reporting, and sharing. If possible, find one that includes Wi-Fi or Bluetooth for easy data transfer to your phone or computer.

Specific units will even allow you to stream in real time or integrate with the inspection management system, making your workflow faster and more organized.

Final Thoughts

When selecting a thermal imaging camera, it is often a matter of sitting down and asking the right questions about what you need and what features you want. A smart device that meets the required standards and has resolution, temperature range, sensitivity, field of view, and durability is essential, as this will enhance your work’s efficiency. The right features will ensure that your thermal imaging camera is valuable for years, whether diagnosing electrical faults, doing energy audits, or just exploring the outdoors.